Process

The Process

At Brahmam, the best TMT bar manufacturers, especially in Southern India, we follow a scientifically tested and proven process. The rigid industrial standards coupled with the latest technological advancements help us in producing products of consistent superior standards that are sought after globally

HOW ARE THE BEST TMT RODS MADE?

- Step 1: Iron Making

- Step 2: Steel Melt Shop

- Step 3: Rolling Mill

- Step 4: Quenching

- Step 5: Self-Tempering

- Step 6: Atmospheric Cooling

Iron Making

Mined Coal and Virgin Iron Ore and coal are shipped to the plant for DRI where Iron Ore is reduced using Coal at 1150°C in Rotary kilns.

Steel Melt Shop

DRI, Pig Iron and Ferro Alloys are added in furnaces and melted at 1650°C. The molten metal after removal of slag is taken to LRF for removal of unwanted Sulphur and Phosphorus. Then the molten and refined steel is solidified into high-quality billets.

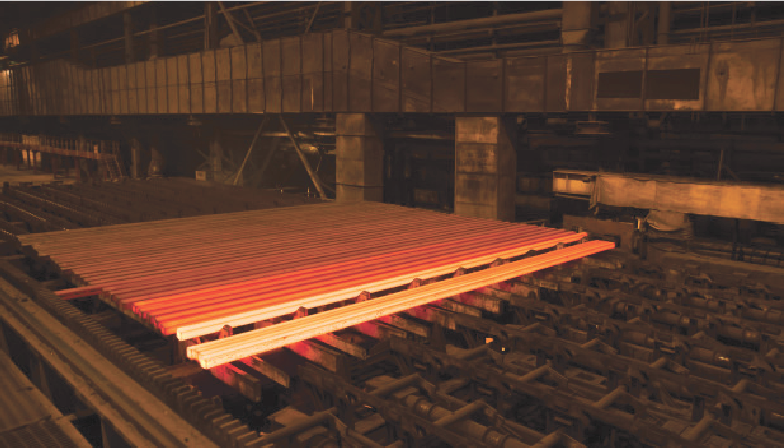

Rolling Mill

The G20 billets are directly charged to the High UTS Quenching and Self Tempering (HURST) rolling mill where it reduced to bars or 1050°C.

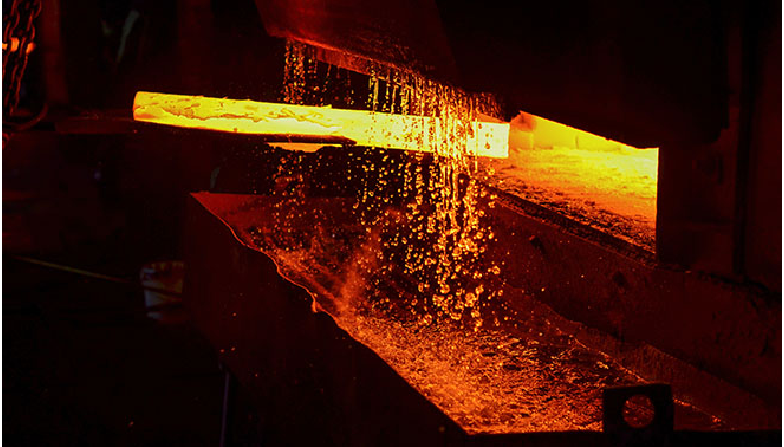

Quenching

The hot-rolled bars are rapidly cooled with RO water through special spray nozzles. This helps in the formation of Martensite rim with a hardened outer layer while the core remains hot.

Self-Tempering

Heat transfers from the hot core to the surface, tempering the outer Martensite rim and an intermediate ring of Martensite and Binate is also formed. This is known as the Tempcore process.

Atmospheric Cooling

The bar is cooled slowly at the automatic cooling bed, where the core is transferred into a ductile Ferrite- Pearlite structure. The stronger surface with a ductile core gives Brahmam TMT Rods its unique characteristic

Got any questions? Call us today!